Field Services

We Come to You

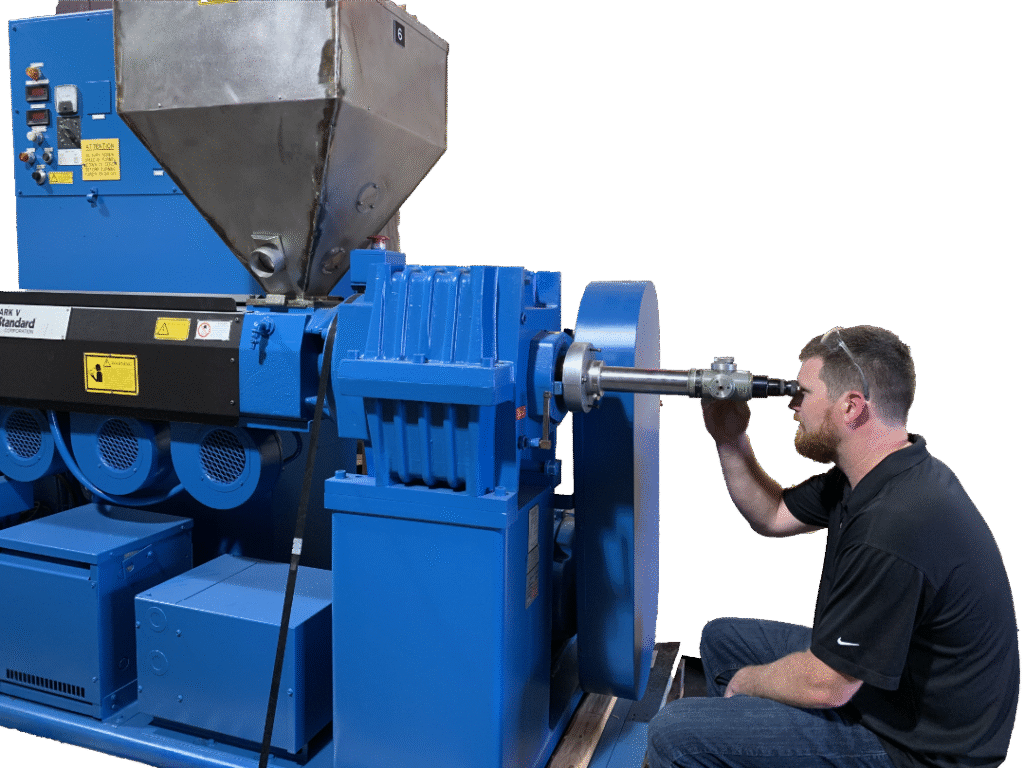

Optical Alignment

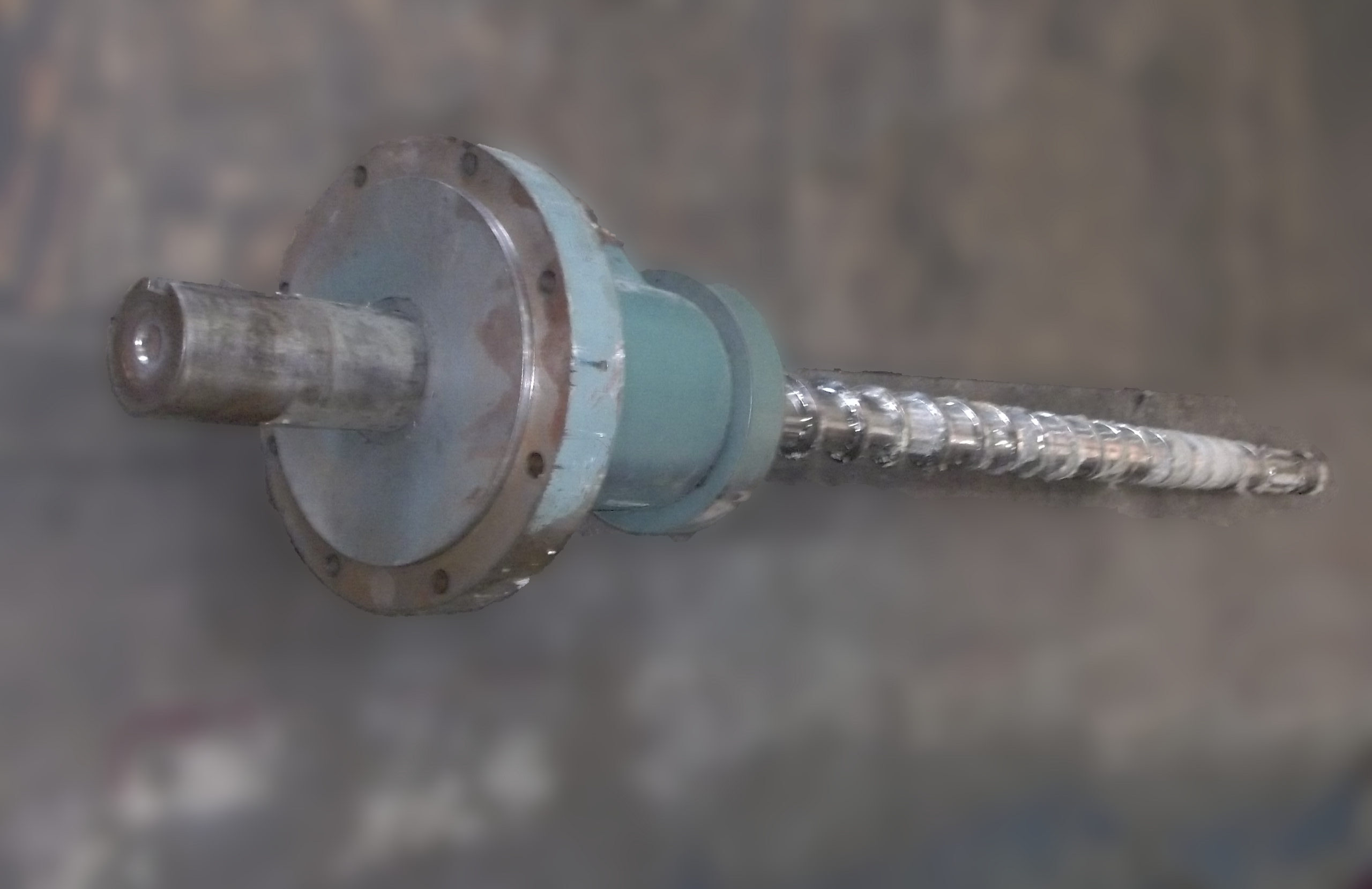

Feed Screw Measuring

Troubleshooting

Line Alignment

Motor Alignment

PM Inspections

Electronic Barrel Measuring

Stuck Feed Screw Removal

Installation & Maintenance

Need us onsite? No problem.

Our experienced field techs bring the tools, expertise, and precision alignment equipment to get the job done right.

Optimize Performance and Extend Lifespan with our screw & barrel services!*

Want to get the most out of your equipment and avoid costly downtime? Our borescope and precise measurement services give you the critical insights you need to proactively manage your screw and barrel health.

Here’s how we help you maximize efficiency and minimize surprises:

Precision Measurement: Our expert technicians come directly to your facility, with precise equipment to accurately measure your screws and barrels.

Comprehensive Wear Analysis: We meticulously document all our findings, delivering a detailed report that includes an easy to understand spreadsheet and a clear, visual wear and tear chart.

Proactive Maintenance Planning: With our detailed report in hand, you can track wear trends over time, allowing you to accurately predict when it’s genuinely time for replacement. This means you can schedule maintenance proactively, avoid unexpected breakdowns, and get the most out of your investment.

*Important Note on OEM Guidelines:

While our inspections provide invaluable data, it’s crucial to always refer to and follow your Original Equipment Manufacturer’s (OEM) recommendations. Each manufacturer has specific preventive maintenance schedules and oil recommendations that are essential for optimal performance and longevity. Our service complements these guidelines, giving you an even clearer picture of your equipment’s condition.

Borescoping

We have an experienced and professional staff prepared to assist you with your special needs. Optical alignment of your barrel, whether it be because a barrel has been replaced or for preventive maintenance, is one the most common requests from our customers. Remember, there is typically only .012″ clearance between a 6″ barrel and screw, that’s only .006″ per side, and it does not take much misalignment to cause wear problems. Barrel and screw measurements are usually taken at this time to keep you informed of the condition of your machine. Once the technician has returned, charts of the wear will be sent to you for your records.

Installations and Alignments

Initial alignments of new equipment or equipment being moved are another of the services we offer, ranging from simple wire and cable installations to very complex cast film and blown film line alignments. We know the importance of quality installation from the beginning, insuring a smooth startup and a quality product for your customers.

Stuck Screw Removal

Stuck feed screws are, unfortunately, a part of the extrusion business. Pieces of steel, wrong blends or power outages create difficult situations and unwanted downtime all too often. Our technicians have removed some of the most difficult all over the country, removing some of the strangest objects you could imagine. Typically in one to two days we can have the screw out, the barrel clean and most important of all, your extruder producing again.

Feed Screw Measuring

Barrel Measuring

PM Inspections

Line Alignment

Installation & Maintenance

Our field service technicians provide service worldwide.

Call us to today and let’s discuss how we can help you with your extrusion needs.