We're the Experts for Gearbox & Extruder Rebuilds

Looking for someone you can truly trust with your critical gearbox repair? You’ve found us! We’ve become one of the most respected extruder service providers for gearbox and extruder rebuilding. Simply put, we’re known for:

Expertise

Texas Extrusion Service knows these machines inside and out.

Reliable Results

We get your equipment running like new.

Putting You First

Your uptime and bottom line are our priority.

Choose the proven team for dependable, expert service.

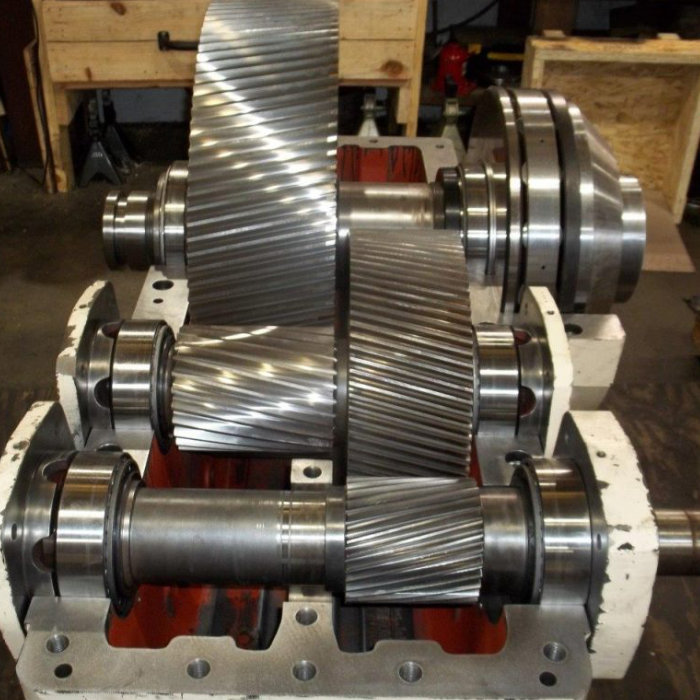

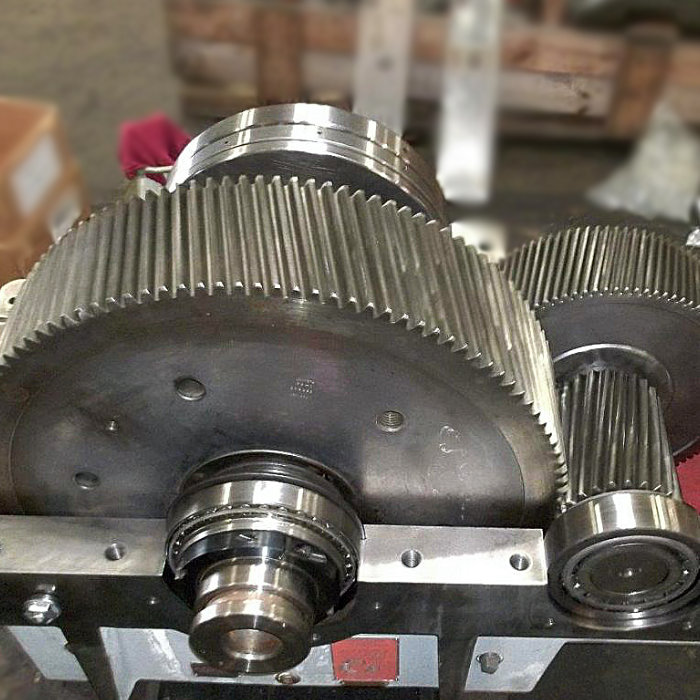

Reliable Gearbox Rebuilds

When your gearbox needs a rebuild, you need it done right and you need it fast. Here at Texas Extrusion Service, we’ve streamlined our process to get your equipment back up and running with minimal downtime.

Our Gearbox Repair Process: Quality and Assurance

When your gearbox arrives at our facility, our commitment to quality begins. Our process is designed for thoroughness and clear communication, ensuring you receive a reliable, warrantied repair.

Here’s what you can expect:

- Detailed Evaluation: Upon arrival, we begin with a precise check on all shafts. This initial step helps us identify any immediate signs of looseness or wear that could indicate underlying problems. Your gearbox is then carefully disassembled and thoroughly evaluated by our team of technicians. We inspect every component to identify all necessary repairs.

- Comprehensive Repair Quote: Based on our detailed evaluation, we generate a comprehensive report outlining all findings. This report forms the basis of your repair quote, which will be submitted to you for your complete review.

- Approval & Scheduling: Once you’ve reviewed and approved the quote, simply issue a purchase order. Upon receipt, your gearbox will be efficiently worked into our repair schedule.

- Testing & Warranty: Before your gearbox leaves our shop, it undergoes a minimum of four hours of no load test running to ensure optimal performance and reliability. Furthermore, all our gearbox repairs are backed by a full one year warranty, providing you with confidence in our workmanship.

We are dedicated to delivering a high quality repair that gets your operations back up and running efficiently.

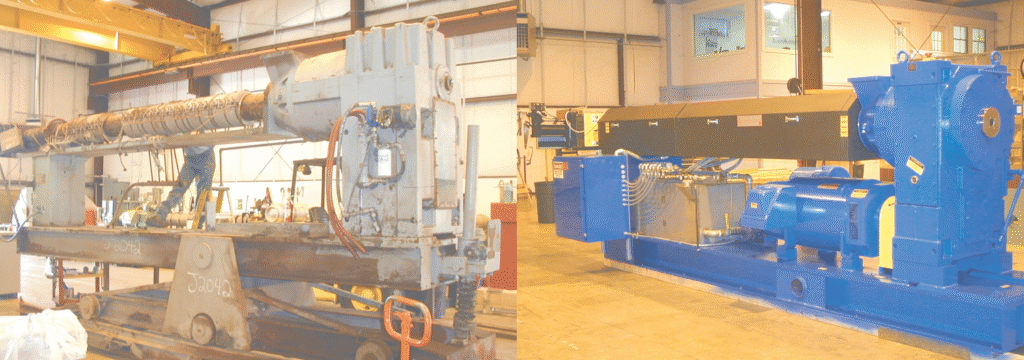

Extruder rebuilding return to “like new” condition

Extruder Rebuilding: Modernize Your Equipment, Optimize Your Operations

At Texas Extrusion Service, Inc., we specialize in breathing new life into existing extruders. We update older equipment into fully functional, modern machines that boost performance and efficiency to help increase your profitability..

Our Comprehensive Rebuilding Process

Our approach involves a thorough process to ensure your extruder is returned in excellent working condition:

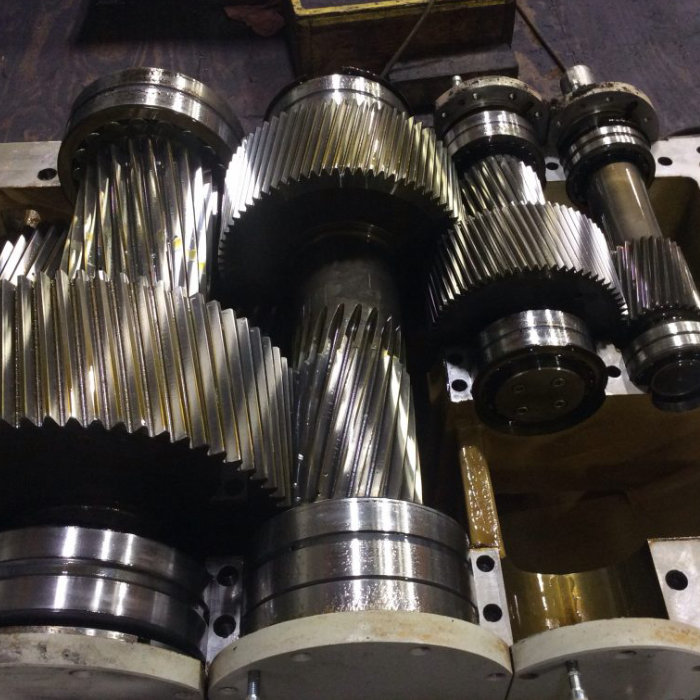

- Complete Disassembly and Gearbox Overhaul: We begin by inspecting and then fully disassembling the extruder. The gearbox is then meticulously rebuilt, providing a robust and reliable foundation for the machine.

- New Components for Enhanced Performance: We integrate a new barrel and screw, selected to optimize your specific extrusion process. New heaters and an updated cooling system are also installed to ensure precise temperature control and improved efficiency.

- Updated Controls and Power Systems: The motor and drive are evaluated, and either updated or replaced to meet current performance standards. We also update or replace the control panel, offering improved functionality and user experience.

Quality, Testing, and Cost Effectiveness

Upon completion, each rebuilt extruder undergoes thorough testing to ensure it meets our quality standards and is ready for immediate production upon return to your facility. This service often represents a significant cost advantage, typically amounting to approximately two thirds the investment of a new extruder. This allows for substantial savings, enabling you to allocate resources within your company.

Extend your extruder’s L/D

Looking to gain more processing length and improve efficiency? We can help with design changes for your extruder itself, extending its L/D for greater performance.

Extruder Rebuilds

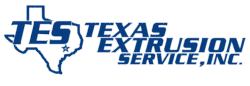

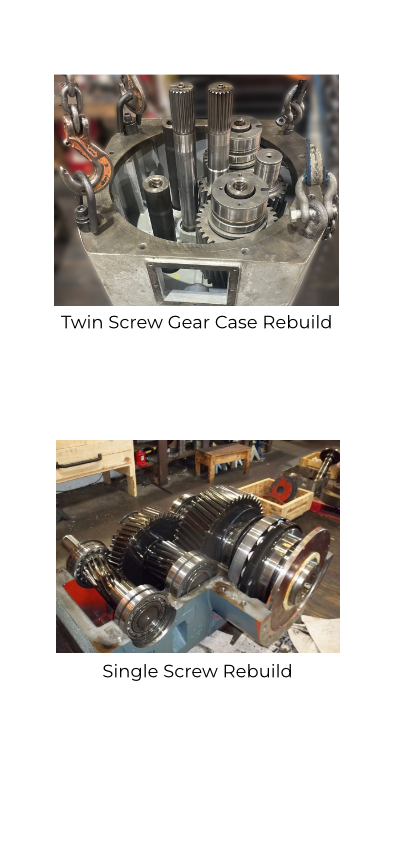

Gearbox rebuilding

Gearbox Rebuilds

Need Help with your gearbox?

Our technicians have over 40 years experience in most gearbox manufacturers, including:

- Alpine

- Amarillo

- Baker Perkins

- Battenfeld

- Berlyn

- Brevini

- Coperion

- Cone Drive

- Crown

- David Brown

- Davis Standard

- Egan

- Eissenbeiss

- Entwistle

- Erema

- Falk

- Flender

- Foote-Jones

- Gloucester

- Hartig

- HPM

- Johnson

- Killion

- Knodler

- Koellmann

- Kodiak

- KraussMaffei

- Link-Belt

- Lufkin

- Maillefer

- Maplan

- Marley

- Merritt Davis

- Nuttall

- Philadelphia

- PIV

- Prodex

- Rossi

- Reifenhauser

- Sterling

- Thyssen

- Werner & Pfleiderer

- Windmoller & Holscher

- Zambello

Motor and Drive packages

These packages are available in AC or DC from 1 to 1000HP with many manufacturers available. Control Techniques Digital DC and General Electric AC Vector & Digital DC available.

Onsite installation, alignment and startup services can also be included in quoted price packages.

Feed Section Relining – Bimetallic Liners

We borescope your existing feed throat and install a removable, bimetallic liner just like the one in your barrel. We have many different makes and sizes, relined and in stock to ease your downtime concerns. We ship your relined throat, and you ship your worn throat back.

Screw Rebuilding

Sometimes, a rebuild is the smartest choice. We offer expert rebuilds for screws and barrels, restoring them to optimal performance and often at a fraction of the cost of new.

We provide new screws and barrels in any size to perfectly match your specifications. But we don’t stop there. Our expertise allows us to offer custom design and design changes.

Need a custom solution? We can design new components from the ground up or make precise modifications to existing designs to optimize your process.

Custom Retrofits – Water/Air Conversions – L/D Conversions

From L/D conversions capable of running today’s complex polymers, to changing your barrel cooling from water to air, Texas Extrusion Service can transform your extruder either in your plant or in our facility.

One of the most popular retrofit projects as of late has been installing a new gearbox onto your existing extruder. We have replaced old and tired gearboxes upgraded to withstand the higher demands of today’s new feed screw designs.

Screw Blueprinting for New

As more complex polymers are developed and introduced into today’s marketplace, the need for innovative screw designs has increased. We have the resources to help with redesigning your feed screws. Our competitive pricing allows our customers an excellent alternative with quality and dependability.

We specialize in in-house rebuilds and repairs for existing equipment.

To speak with a representative, please contact us today at 1-281-350-2288, or stop by our Spring (Houston area) location.