Serving the Plastics Industry for Over 40 Years

Keeping Your Production Running with Precision, Reliability, and Experience

At Texas Extrusion Service, we are committed to helping you maximize the longevity and reliability of your plastic extrusion equipment. With over 40 years of experience and a team of technicians skilled in extruder service and repairs, we provide solutions to keep your production running smoothly.

We recognize the challenge of balancing daily production demands with routine maintenance. That is why manufacturers across the industry rely on us for expert plastic extruder repair services, from barrel replacements and gearbox rebuilds to plastic extruder rebuilds, new feedscrews, barrels, optical barrel alignments, stuck screw removals, screw rebuilds and screw and barrel repairs. Whether you are facing an unexpected equipment failure, dealing with a sudden breakdown, or proactively planning extruder maintenance, our experienced team is ready to assist.

Products and Services

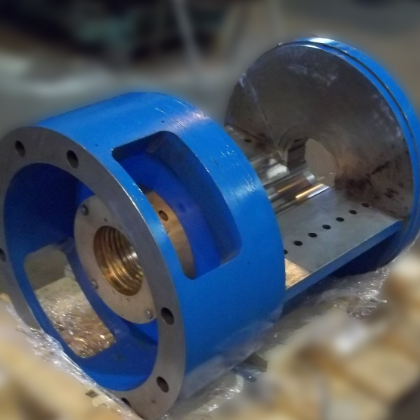

We provide a comprehensive range of solutions to meet all your plastics equipment needs. In addition to onsite service and maintenance, we specialize in in-house rebuilds and repairs for existing equipment

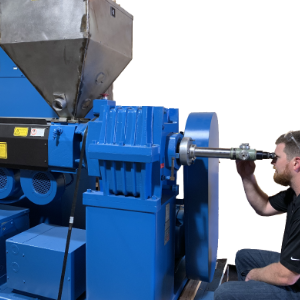

Need us on site? No problem. Our experienced field techs bring the tools, expertise, and precision equipment to get the job done right.

Our fully equipped facility allows us to deliver high quality repairs and rebuilds with fast turnaround times.

We also offer equipment to elevate your production performance.

- New Feedscrews

- New Barrels

- Screen Changers

- Melt Pumps

- Motors & Drives

- Custom Build Control Cabinets

- New Equipment

Explore our current inventory of preowned extruders, gearboxes, screws, motors, heat exchangers, hoppers, and other extruder components.

Equipment

Over 40 years repair and rebuild experience in most gearbox manufacturers

Alpine Gearbox

Amarillo Gearbox

Baker Perkins Gearbox

Battenfeld Gearbox

Berlyn Gearbox

Brevini Gearbox

Coperion Gearbox

Cone Drive Gearbox

Crown Gearbox

David Brown Gearbox

Davis Standard Gearbox

Egan Gearbox

Eissenbeiss Gearbox

Entwistle Gearbox

Erema Gearbox

Falk Gearbox

Flender Gearbox

Foote-Jones Gearbox

Gloucester Gearbox

Hartig Gearbox

HPM Gearbox

Johnson Gearbox

Killion Gearbox

Knodler Gearbox

Koellmann Gearbox

Kodiak Gearbox

KraussMaffei Gearbox

Link-Belt Gearbox

Lufkin Gearbox

Maillefer Gearbox

Maplan Gearbox

Marley Gearbox

Merritt Davis Gearbox

Nuttall Gearbox

Philadelphia Gearbox

PIV Gearbox

Prodex Gearbox

Rossi Gearbox

Reifenhauser Gearbox

Sterling Gearbox

Thyssen Gearbox

Werner & Pfleiderer Gearbox

Windmoller & Holscher Gearbox

Zambello Gearbox

Why Choose Texas Extrusion Service?

40+ Years of Industry Experience

Expertise Across All Major Gearbox Brands

Responsive Field Service Teams

Commitment to Quality & Uptime

Customized Solutions to Meet Your Requirements

FAQs

What do I need to schedule someone to come to my facility?

Here’s how to schedule your visit:

Just give us a call! You can reach our Field Service Coordinator at 281-350-2288. They’re ready to assist you in scheduling a technician out to your plant.

To ensure a smooth and swift scheduling process, please have the following information handy when you call:

- Your Name and Contact Information: This includes your direct email address and phone number.

- Plant Location: The full address of the facility where our where we will be performing service.

- OEM Manufacturer: The original equipment manufacturer of the gearbox (e.g., Davis Standard, Battenfeld, Alpine, etc.).

- Gearbox Specifications: The correct size of the gear case, and whether it’s metric or standard.

- Pictures: Providing pictures of issues you are having help the technician have the right tools ready for the service visit.

Having these details ready will help us understand your needs and send the right expert with the right tools to your site.

Do you borescope and do measurements?

Yes, our advanced borescope and precise measurement services give you the critical insights you need to proactively manage your screw and barrel health.

Here’s how we help you maximize efficiency and minimize surprises:

On-Site, Precision Measurement: Our expert technicians come directly to your facility, armed with state-of-the-art, precise equipment to accurately measure your screws and barrels. We don’t guess; we provide data-driven insights.

Comprehensive Wear Analysis: We meticulously document all our findings, delivering a detailed report that includes an easy-to-understand spreadsheet and a clear, visual wear and tear chart.

Proactive Maintenance Planning: With our detailed report in hand, you can track wear trends over time, allowing you to accurately predict when it’s genuinely time for replacement. This means you can schedule maintenance proactively, avoid unexpected breakdowns, and get the most out of your investment.

*Important Note on OEM Guidelines:

While our inspections provide invaluable data, it’s crucial to always refer to and follow your Original Equipment Manufacturer’s (OEM) recommendations. Each manufacturer has specific preventive maintenance schedules and oil recommendations that are essential for optimal performance and longevity. Our service complements these guidelines, giving you an even clearer picture of your equipment’s condition.

Do you offer screws and barrels for my extruder?

Absolutely! Whether you’re looking for brand-new components or a cost-effective rebuild, we offer comprehensive solutions for your screw and barrel needs.

New Screws and Barrels – Designed for Your Success

We provide new screws and barrels in any size to perfectly match your specifications. But we don’t stop there. Our expertise allows us to:

Offer custom design and design changes: Need a unique solution? We can design new components or make precise modifications to existing designs to optimize your process.

Extend your extruder’s L/D: Looking to gain more processing length and improve efficiency? We can help with design changes for your extruder itself, extending its L/D for greater performance.

Revitalize Your Existing Components with Our Rebuild Services

Sometimes, a rebuild is the smartest choice. We offer expert rebuilds for screws and barrels, restoring them to optimal performance and extending their lifespan, often at a fraction of the cost of new.

How can I get a quote for my gearbox repair?

Contact us and we can discuss your repair needs. Our team will assist you every step of the way to prepare your gearbox for a thorough inspection.

When your gearbox arrives at our facility, we don’t just glance at it – we put it through a rigorous, multi-step inspection process to pinpoint any issues and ensure the longevity of your equipment.

Here’s how we ensure a thorough assessment:

- Initial Mechanical Checks: We begin with a precise lift and endplay check on all shafts. This initial step helps us identify any immediate signs of looseness or wear that could indicate underlying problems.

- Comprehensive Disassembly and Internal Scan: Next, we carefully disassemble your gear case. Every internal component is then meticulously inspected for cracks or damage that might not be visible externally.

- Detailed Dimensional Analysis: We precisely measure journal and shaft diameters.

- Transparent Documentation and Recommendations: Throughout this entire process, all our inspection findings are thoroughly documented in a detailed gear case report. Once our comprehensive inspection is complete, we’ll contact you directly to discuss our findings and present you with clear, recommended repair options tailored to your specific needs.

Our goal is to provide you with an accurate assessment so you can make informed decisions about your gearbox repair and maintenance.

How long does an in-house gearbox repair take?

When your gearbox needs a rebuild, you need it done right and you need it fast.

For a standard rebuild, which includes shaft and some housing journal repairs, you can expect an approximate turnaround time of 3-5 weeks. This timeframe can vary slightly based on the extent of the damage we assess during our detailed inspection. We’re committed to precision, so we take the time to ensure every repair is done right.

What if I need new gears?

If our inspection reveals the need for new gears to be manufactured, the lead time is typically 16-18 weeks. This allows for the precise engineering and production of high-quality, custom-made components to ensure optimal performance and longevity.

Do you offer expedited services?

We understand that sometimes, waiting just isn’t an option. That’s why we offer expedited service options designed to significantly reduce lead times on your repairs. If you’re facing a critical deadline, just let us know, and we’ll work with you to explore the fastest possible solution.